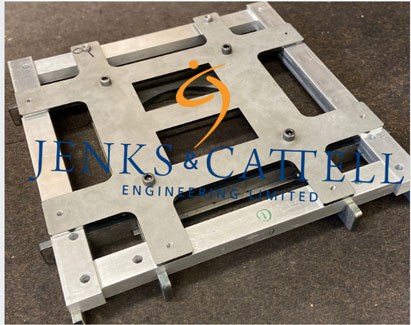

Jenks & Cattell Engineering Ltd are pleased to share with you a prototype weld jig made internally by our quality and engineering teams this week for a customer specific aluminium product which is currently at prototype stage.

Quality is at the core of all that we manufacture at Jenks & Cattell Engineering, thus the importance to manufacture our weld jigs and checking fixtures to ensure all our welded assemblies are to the best quality possible; to achieve customer tolerances and drawing specifications.

For quantities’ over 1,000 per year it is recommended to our customers to invest in a weld jig to ensure the precision and quality is identical on every single part.

The benefit of having a weld jig for both manually welded and robotic products is:

- Improved time efficiency to improve production output and cost

- Less waste is produced

- Precise and consistent weld tolerances

- Ideal for medium-high volume quantities

- Consistent weld seams

Jenks & Cattell Engineering take pride in our welding team and facilities, including CEOC and SAFed approved welding personnel who receive regular training, as well as six robotic welders, 2 manual welding bays and facilities to complete spot, projection and CD welding on a wide range of metals.

A lot of our current portfolio of metal welded assemblies include the welding of accessories including tubes, machined bars/rods, nuts, studs etc… to manufacture a complete mechanical or functional metal assembly to reduce manufacturing miles for our customers to deliver a complete product.