Jenks & Cattell Engineering Ltd are working with numerous alternate energy companies including electric-vehicle, electric-bicycle, offshore wind manufacturers, plus a military vehicle OEM with a key focus on manufacturing lighter vehicles to reduce emissions.

The majority of our customer base focus on producing lower carbon emissions to eliminate environmental pollution, and we operate a Target Zero Programme at Jenks & Cattell Engineering to support these innovations and continuous improvement philosophies with high quality metal components. We have over 135+ years of experience in supplying OEM’s and tiered manufacturers for components including wiring harnesses, battery boxes/trays, busbars, and terminals and target zero defences, accidents, variance, and landfill.

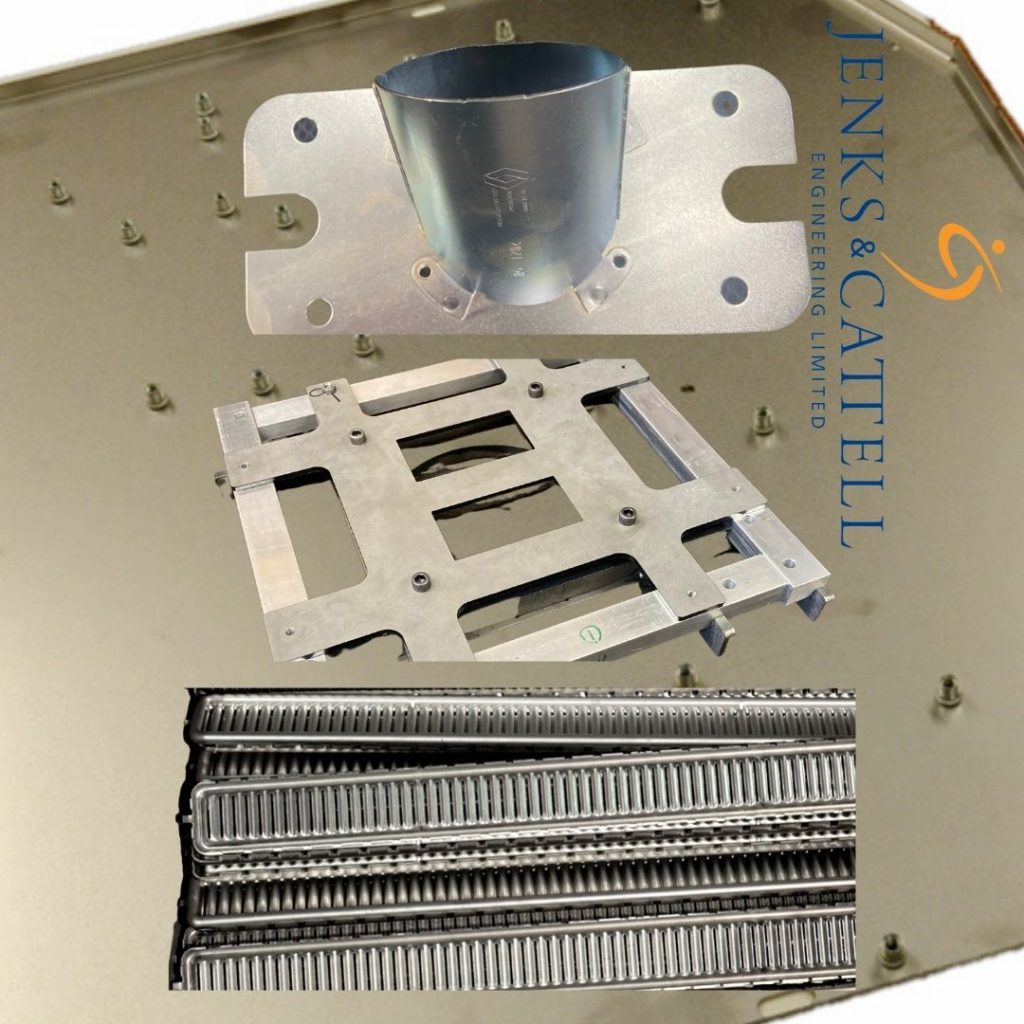

We offer a sheet metal manufacturing services for customer designed products and we can support conception phase projects through to mass volume production; with our engineering team offering support from initial feasibility phase to ensure the most efficient metal manufacturing route.

Alternate energy components and vehicle battery box components can take advantage of our automated equipment including coil-fed progression presses, robotic welders and laser cutting. For over a decade we have recognised the demand for lighter weight metal stampings with the use of aluminium which has driven our investment emphasis to all things aluminium to be ahead of the game with a target of 60% EV, hybrid and hydrogen vehicles being accountable for all automotive sales by 2030. We can laser cut and stamp aluminium sheet (1mm-10mm gauge), and we can robotically, manually, MIG and TIG weld aluminium from our large plant in the West Midlands.

Jenks & Cattell Engineering develop tooling for repeatable quality high volume production at efficient speed and competitive costs, plus we have the capacity to inspect parts to CAD using CMM to facilitate 100% quality and zero defects every time.

As one of the most established metal press workers in the UK, we are a reliable supplier who worked continuously throughout COVID-19 and Brexit despite obstacles. There are incentives for supplier localisation to reduce failure in the supply chain, and we can offer impressive lead times with a 100% delivery performance target. A local nationalised supply base reduces transportation emissions between nodes of the supply chain which prides both chains sustainability. Most of our subcontract supply chain are within a 5-mile radius, which in hand reduces risk of failure to supply to demand.

In 2021, we have recycled all our waste and totalled zero landfill and we use returnable packaging where possible, WEEE directive for electrical waste, and we have invested almost £10,000 in energy efficient lighting and energy saving practises with further continuous improvements to seen throughout 2022.